Desuperheating is an important process that is used in a variety of industrial settings, including power plants, chemical plants, and natural gas processing facilities. In simple terms, desuperheating is the process of reducing the temperature of superheated steam or gases to a desired level before they are used in downstream processes. This process is necessary to ensure that the steam or gases are at the proper temperature to prevent damage to equipment and to improve the efficiency of the overall process.

Here we'll discuss what a desuperheater is, the basic types available, and the theory behind desuperheating.

What is a Desuperheater?

Desuperheating is the process of bringing down the temperature of superheated steam to its saturation point. The equipment used for this process, called a desuperheater, is designed to lower the steam temperature to a proximity of saturation usually within 3°C.

One potential application of desuperheating is in capturing and repurposing the wasted heat in summer. Instead of releasing the heat to the environment, a geothermal desuperheater can extract some of it and transfer it to the water heating system, increasing the energy efficiency of the system. Desuperheaters work by injecting a precise amount of water into the superheated steam. The evaporative cooling action of the water reduces the temperature of the steam, making it ready for downstream use. Using a preheat tank can maximize energy savings.

Basic Desuperheater Types

There are several types of desuperheaters available, each with its own unique design and method of operation. Common types of desuperheaters include:

Attemperator Desuperheater

These are ideal for situations that involve steady load conditions and a need to minimize pressure loss. They can provide better turndown when they are mounted in a vertical position.

Venturi Desuperheater

This is the process of lowering the temperature of steam by introducing it to water directly. This method is typically employed in situations where it is not feasible to use atomized steam.

Annular Venturi Desuperheater

These can adjust to a wide range of flow rates and conditions. They have a high turndown ratio, meaning they can effectively reduce steam temperature across a broad range of operating conditions.

Annular Venturi Orifice Desuperheater

This type has a greater turndown capacity than other types of desuperheaters. Additionally, the design of the annular venturi orifice desuperheater prevents the buildup of unvaporized water in the pipeline.

Mechanical Atomizing Dump Desuperheater

This type of desuperheater is a cost-efficient solution for reducing the temperature of high steam flow in large pipelines. It was specifically designed to desuperheat large volumes of steam economically.

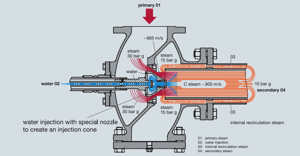

Steam Ejector Atomizing Desuperheater

This type is used in scenarios where flow fluctuates significantly and a desuperheating station that serves multiple functions is needed.

Surface Absorption Desuperheater

Generally used where space limitations are a factor and requirements of minimum water carryover exist, surface absorption desuperheaters work by forcing steam to come in contact with wetted metal reaction rings.

For most desuperheater types, water pressure requirements are the same as the steam line pressure.

Basic Desuperheating Theory

As previously stated, desuperheating is the process of reducing the temperature of superheated steam to its saturated state using desuperheater equipment, which can produce discharge temperatures that are close to saturation, usually within 3°C of the saturation temperature. However, it's also possible to design desuperheaters for discharge temperatures that are above 3°C above saturation.

There are two main types of desuperheaters:

- Indirect contact desuperheaters: The cooling medium (like liquid or gas) does not come into direct contact with the superheated steam. Examples of this type are shell and tube heat exchangers.

- Direct contact desuperheaters: The cooling medium (usually water) comes into direct contact with the superheated steam. This is the most common type of desuperheater, used for desuperheating steam.

Desuperheater refrigeration equipment comes in all sizes and shapes and utilizes various mechanical and energy transfer techniques to achieve the desired performance within the limits of the system environment. Although appearing simplistic in design, a desuperheater must integrate with a wide variety of complex thermal and flow dynamic variables to be effective. Units designed for discharge temperatures above 3ºC above saturation are possible and often used.

To learn more about desuperheaters, contact us. If you already know your system's needs, save time by requesting a quote.