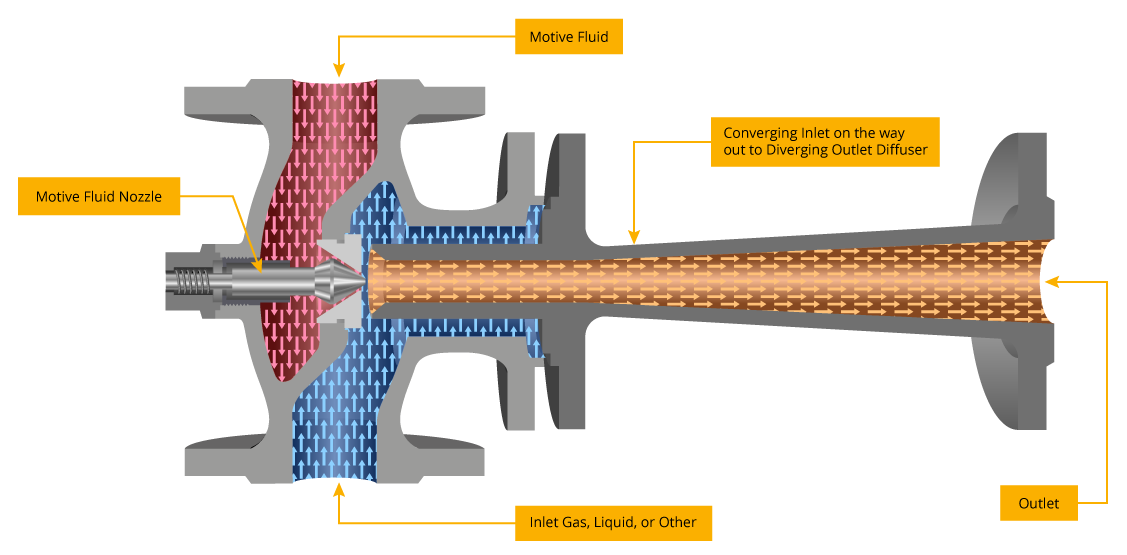

Ejector pumps (also called jet pumps) are a special version of a 3-way valve that works based on a fluid dynamics concept known as Bernoulli’s principle: pressure and fluid velocity are inversely proportional causing the Venturi effect. Ejector pumps are controlled by an electric or pneumatic actuator. These static devices mount to a pipeline system and are connected to both a high-pressure water or steam supply and another vessel with a low-pressure fluid. The ejector has two inlets leading to a nozzle, which is incorporated into an asymmetrical, hourglass-shaped tube called a diffuser. The components are often made of brass, cast iron, carbon steel, or stainless steel for durability and low maintenance, effectively offering longer lifespan and energy-saving service.

High-pressure steam or water, called the motive fluid, enters through one inlet and passes through the nozzle, which converts its pressure to velocity. As speed increases, a vacuum forms and the lower-pressure fluid is drawn in through the suction inlet.