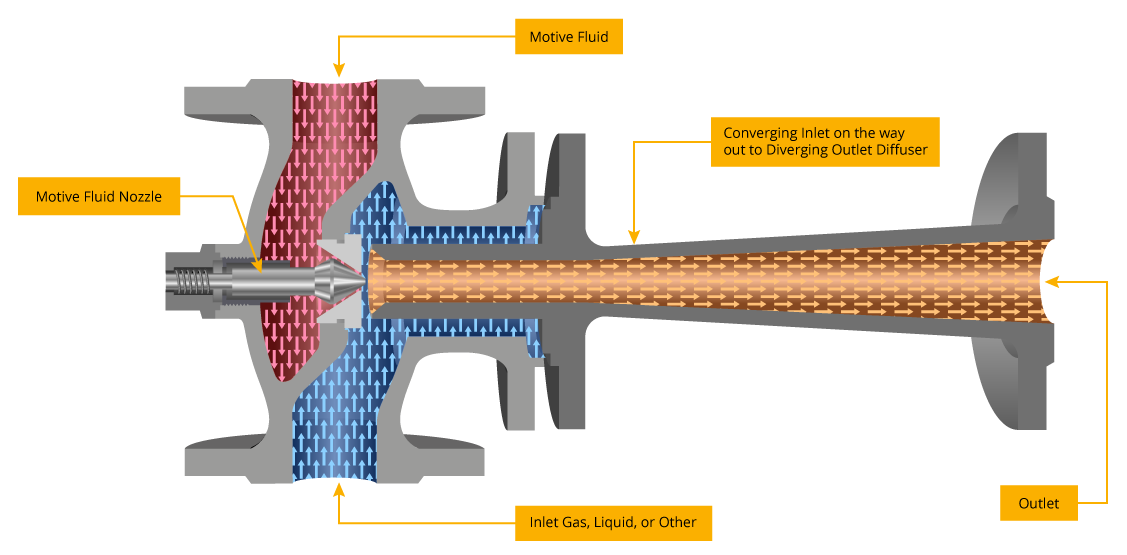

Ejector pumps (also called jet pumps) are a special version of a 3-way valve that works based on a fluid dynamics concept known as Bernoulli’s principle: pressure and fluid velocity are inversely proportional causing the Venturi effect. Ejector pumps are controlled by an electric or pneumatic actuator. These static devices mount to a pipeline system and are connected to both a high-pressure water or steam supply and another vessel with a low-pressure fluid. The ejector has two inlets leading to a nozzle, which is incorporated into an asymmetrical, hourglass-shaped tube called a diffuser. The components are often made of brass, cast iron, carbon steel, or stainless steel for durability and low maintenance, effectively offering longer lifespan and energy-saving service.

High-pressure steam or water, called the motive fluid, enters through one inlet and passes through the nozzle, which converts its pressure to velocity. As speed increases, a vacuum forms and the lower-pressure fluid is drawn in through the suction inlet.

Next, the fluids mix in the first part of the diffuser called the converging inlet, which gradually narrows. The mixture passes through the throat section of the tube and into the diverging outlet, which gradually widens. Here, pressure is adjusted to an intermediate level between the two original pressures. The steam or liquid expelled from the diffuser is normally hot and is used with heat-resistant equipment.

Ejectors allow heated water or steam to be distributed to multiple circuits without a pump and a control valve. Ejectors can also be used to capture and reuse process steam, create suction for vacuum sealing and drying systems, desuperheat superheated steam, or improve the energy efficiency of thermal transfer applications.

Baelz makes two different types of ejectors: steam and water ejectors. They are excellent choices for improving operational efficiency, saving energy and equipment costs, and investing in long-term productivity.

Steam Ejectors

Steam ejectors use high-pressure steam as the motive fluid to create a vacuum within a system. They provide distinct advantages such as reduction of steam loss, increased machine performance, and improved energy efficiency.

Baelz steam ejectors combine steam with water for a wide range of applications, including cooling superheated steam as a desuperheater, conditioning saturated steam, and condensing steam for reuse in other thermal transfer applications.

Steam ejectors can be installed in either recirculation or compression systems for improved efficiency:

- Recirculation Systems: To increase thermal performance by up to 15% and steam savings by up to 5%.

- Compression Systems: To save energy, with direct steam savings of 10 to 30% or more.

The baelz 590 steam ejector features a flanged connection for recirculation and compression of exhaust vapor. Material options include cast iron or carbon steel, with stainless steel internal components (i.e., plug, spindle, and nozzle).

Water Ejectors

Like steam ejectors, water ejectors use liquids (mainly water) as a propulsion medium. The propulsion flow is accelerated in the nozzle generating a negative pressure that creates a vacuum where both flows are mixed resulting in kinetic and thermal energy being exchanged.

Baelz water ejectors are often used as an alternative to water control valves. They are commonly used for applications requiring temperature control, flow-variable recirculation, differential pressure control, or for preventing unwanted circulation of fluids.

Typical applications include cooling thermal fluid in the lumber industry; heating, hot water, and ventilation systems in buildings; and pumping and mixing for pneumatic conveying systems.

Baelz 480 water ejectors feature flanged connections to mix and recirculate liquids and can be used with water, thermal oil, or other liquids. Material options include cast iron or carbon steel with stainless steel internal components (i.e., plug, stem, and nozzle).

Desuperheaters

A unique ejector application is desuperheating steam in power generation plants, petrochemical plants, and refineries. There is often sufficient superheated steam to convert to saturated steam for industrial heat applications. Desuperheaters reduce the temperature of superheated steam to within 3°C of its saturation temperature by introducing a precise amount of cooling fluid (i.e., steam or water). At this lower temperature, the steam is suitable for heat transfer uses. This is an excellent way to conserve and reuse heat and steam, reducing downtime for steam generation. It also saves energy and associated costs.

Find the Right Ejector from Baelz NA

Baelz NA provides energy-saving components and engineered systems for controlling process heating and cooling applications. We manufacture and distribute many types of ejectors, controllers, actuators, control valves, and more. All of our products feature high-quality construction, few moving parts, and long service life while helping to improve sustainability and reduce energy consumption.

Contact us or request a quote to speak with a specialist about the best ejector solution for your application.