At Baelz, our commitment to high-quality products and a long service life goes hand-in-hand with low energy consumption, and our controllable components are a crucial part of this equation. At Baelz, we believe efficiency equals sustainable planning, reduced system components, consistently high quality, less energy consumption, and guaranteed long service life. This approach has helped our clients save money, reduce downtime, and improve production. Energy-saving automatic components offered by Baelz include Actuators, Control Valves, Controllers, and Ejectors.

Highlight: Controllable Baelz Ejectors

While a conventional circulation pump can last a decade, ejectors typically perform for twice that long. Many of our controllable solutions have been working reliably for more than 40 years, drastically reducing the need for expensive and time-consuming repairs and replacements.

Baelz ejectors are a four-in-one energy-saving solution that:

- Create circulation where it’s needed

- Adjust circulation volume according to heat requirements

- Regulate temperature

- Compensate for differential pressure fluctuations

We offer two types of ejectors, steam and water. In its own way, each of these ejectors has the ability to save energy and reduce your operating cost.

Steam Ejectors

Easy to install and maintain, steam ejectors create suction using steam as the motive fluid. The Baelz steam ejector efficiently utilizes all available energy to reduce steam loss and increase machine performance in all steam systems.There are four efficiency gains that can be achieved from using Baelz steam ejectors:

- Power consumption

- Waste heat recovery

- Reduced maintenance cost

- Equipment efficiency

How Baelz steam ejectors save energy and reduce operating cost:

- Baelz steam ejectors can connect to a condensate system to reuse energy that would normally be wasted. In a system like this, the installation of steam ejectors also means fewer maintenance personnel are required to clean steam traps associated with this application.

- Rather than using a pump and motor loop, a steam ejector will only utilize electricity to move the actuators within a system to save electrical energy.

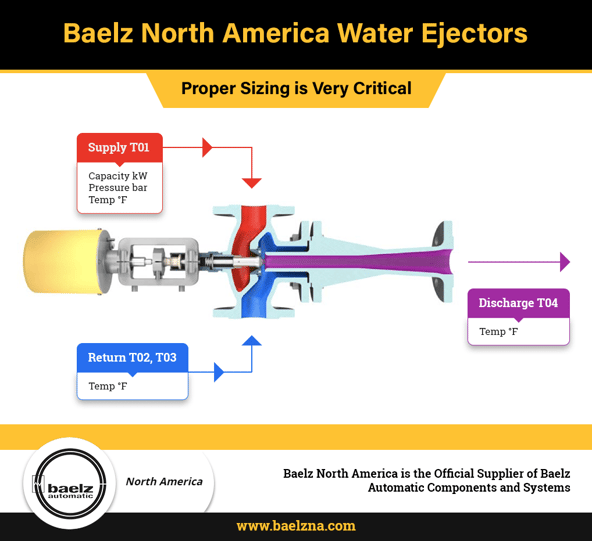

Water Ejectors

Water ejectors can be used in place of water control valves to save more than 15% in maintenance, operation, and energy costs over time. The motive fluid’s potential energy is converted into kinetic energy as it passes through the converging-diverging nozzle. For single-pump applications, that velocity provides plenty of differential pressure to draw and discharge fluids. Water ejectors improve energy efficiency while giving you more control over water distribution. They’re commonly used in the wood industry to cool hot oil, in pneumatic conveyance for pumping and mixing, and more.

There are two efficiency gains that can be achieved from using Baelz water (and thermal fluid) ejectors:

- Power consumption

- Reduced maintenance cost

How Baelz water ejectors save energy and reduce operating cost:

- Pump actuating rather than actuating energy produces significant cost savings. Instead of distributing the water to secondary circuits, each of which would require its own control valve and secondary pump, our solutions allow one pump to supply all the control loops requiring less energy than you would need to power multiple pumps.

- It’s also faster to install. Installation of a water ejector means fewer components to install. Optimized installation time saves money in the short term, and contributes to consistent operation and long system life. With fewer working parts, there is less potential for a breakdown.

Invest in Energy Saving Components

A high-quality component is an investment in the future of your company, a time and money-saving strategy that will impact your bottom line for years to come. Our company has more than a century of experience producing valves, actuators, ejectors, and more for applications in the water treatment, automotive, food, wine, marine, chemical, and power industries around the world. For more information about steam and water ejectors and other energy-efficient automatic components, contact the experts at Baelz North America or request a quote.