Ejectors are small units within a heated fluid system that can distribute that fluid evenly throughout a defined area. Ejectors work without pumps; they use the Venturi principle to release and distribute either steam or heated water (depending on the system). At Baelz North America, we supply controllable pneumatic and electric ejectors, which each have a suction inlet, motive inlet, and discharge outlet arranged as a three-way valve to discharge the fluid. Learn more about the differences between our steam and water ejectors for various systems.

Steam Ejectors vs. Water Ejectors

Steam ejectors and water ejectors from Baelz NA are both controllable ejectors that can reliably and consistently distribute fluid throughout an area. Our steam ejectors are primarily used in these applications:- In recirculation systems that reduce the total energy consumption of a machine system

- In compression systems that can save between 10-30% of generated steam in a system

- Commercial and industrial bakery ovens

- Fertilizer processing

- Oil distillation, deodorization, and other petrochemical applications

- District Heating and Cooling (HVAC)

- Textile and paper drum dryers

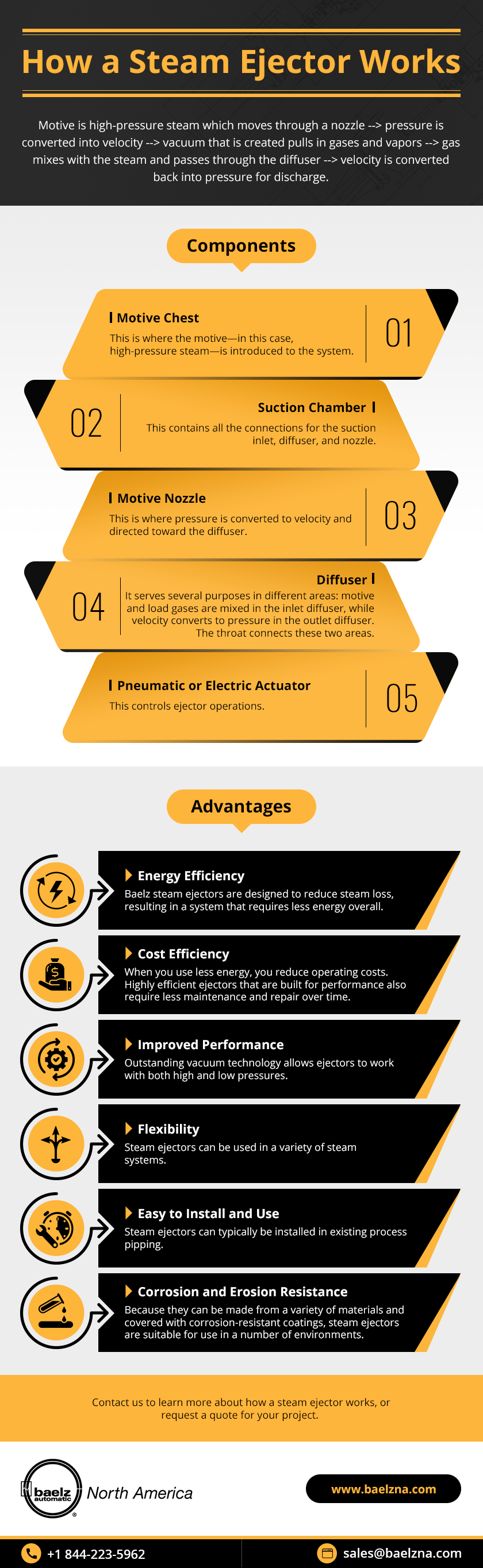

Water ejectors also help facilities save electrical energy. They can replace water control valves in high-pressure systems to reduce energy consumption in heating and ventilation systems. Water ejectors can also control the circulation of fluid in a system and maintain temperature. Water ejectors can be slightly more simple than steam ejectors; rather than being a three-way valve with a special steam ejector plug, these tools have a motive chest, suction chamber, motive nozzle, diffuser, and actuator through which the fluid moves.

Water ejectors are commonly used in conveyance systems for pumping and mixing fluids, for HVAC and water heating applications in commercial, industrial, and municipal buildings, and in research and development.

For both types of fluid ejectors, it’s important to choose the right tool for a given application. At Baelz NA, we can help you determine the right steam or water ejector based on the size requirements, primary steam pressure, low-pressure steam levels, and other factors.

Ejectors From Baelz North America

Baelz is a leading provider of steam and water ejectors throughout North America. Our ejectors can be used across a wide range of applications in commercial and industrial settings to increase energy efficiency in closed steam systems, control heating systems, and more. Our ejectors are built to resist corrosion and are easy to install with few maintenance demands. Users can enjoy increased energy efficiency without additional process demands. Our pneumatic and electric ejector units have a 20-year lifespan.Contact Baelz North America for Steam and Water Ejectors

Controllable ejectors outperform comparable valves and provide excellent system control for a wide range of heating and mechanical processes. Contact our team today to learn more about our water and steam ejectors or to start your order.