Thermocompressors are a specialized type of steam ejector that make it possible to reclaim or reuse low-pressure steam that would otherwise be lost to the atmosphere – including all the energy that’s still in it They boost low-pressure steam to a higher pressure so it can be redirected to other systems, including space or water heating, evaporation, distillation, or vacuum creation.

Thermocompressors are particularly beneficial in applications that require either:

- Consistent temperature control, or

- Flexible temperature variations throughout different parts of the process

Industries including paper manufacturing, food processing, petrochemical facilities, refineries, textiles, steel plants, distilleries, dairies, and chemical plants take advantage of thermocompressors to minimize wasted energy and lower operational costs.

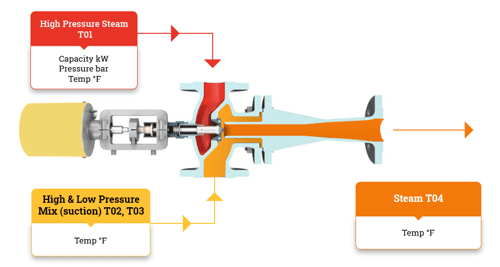

A thermocompressor has three components: a nozzle, a mixing section, and a diffuser. A higher-pressure motive steam enters the nozzle area, where it is compressed and its pressure becomes kinetic energy. Following Bernoulli’s principle, there is a decrease of pressure allowing the low-pressure steam to be pulled in. Then both enter the mixing section. As the mixture moves into the diffuser section, the kinetic energy is converted back into pressure. The result is usable steam at an intermediate pressure between that of the original high and low pressures. Baelz thermocompressors have a controlled nozzle with 0 to 100% variable flow, so they combine the functions of a control valve and a standard fixed-nozzle ejector in one device.

This blog explores how thermocompressors are used in two key industries and their role in energy conservation.

Paper Industry

Thermocompressors are widely used in the paper industry, primarily because paper machines rely heavily on steam during production. Steam is used extensively in the drying process, where it transfers heat to the dryer shells to remove moisture from the paper web. However, not all of the steam condenses during this process. A portion of the steam, known as “blow-through steam,” exits the dryer shell along with condensate.

A thermocompressor can be used to capture the low-pressure blow-through steam and mix it with high-pressure motive steam, which can then be reintroduced into the dryer system at an intermediate pressure. This process recycles steam and ensures optimal drying conditions, reducing the overall steam consumption and improving energy efficiency in paper mills.

Industrial Plants

Thermocompressors also have widespread applications in various industrial applications, including, but not limited to:

- Flash tank systems

- Recirculating loop systems

- Steam balancing systems

Thermocompressors in Flash Tank Systems

Flash tanks are commonly used in steam systems to recover energy from condensate; however, the low-pressure steam generated in flash tanks is often underutilized and sometimes just released to the outside, a big loss of energy A thermocompressor addresses this issue by using high-pressure motive steam to extract the low-pressure flash steam and elevate it to an intermediate pressure. This recovered steam can then be reused in other processes, reducing steam waste and enhancing overall efficiency.

Recirculating Loop Thermocompressor Systems

Recirculating loop thermocompressor systems are designed to consume flash steam from equipment such as rotating dryers, heat exchangers, reboilers, and process air units. The thermocompressor uses high-pressure steam as the driving force to capture this flash steam and deliver it back to the steam supply inlet. This process helps maintain the required steam pressure levels for industrial operations while reducing energy waste. (Is done by the steam ejector itself since it is controlled!)

Steam Balancing Systems

Maintaining a balanced steam supply is critical for efficient operations in industrial plants. Thermocompressors are used to balance steam pressure by mixing high-pressure motive steam with low-pressure steam to create an intermediate pressure. As a result, excess steam can be reclaimed instead of vented outside or wasted. This can significantly reduce energy costs and enhance overall steam system efficiency.

Learn More About Thermocompressors

Thermocompressors are a simple yet essential technology for getting the most out of steam, reducing waste, and improving energy efficiency. They can produce significant cost savings by repurposing low-pressure steam while maintaining effective process control.

Baelz North America is a trusted supplier of thermocompressors and steam control solutions that enhance efficiency and sustainability in industrial steam systems. Learn more on our product page or contact us to discuss your application. Or, request a quote to get started with steam reclamation in your facility.

.png?width=300&height=1063&name=What-Are-Thermocompressors--Steam-Ejectors%20(1).png)