Thermocompressors are a type of steam ejector used to increase energy efficiency by recovering the energy in low-pressure waste steam. This low-pressure exhaust from evaporators, cookers, and other process equipment is typically vented to the atmosphere or condensed in cooling towers. Meanwhile, other plant operations may require or use intermediate-pressure steam for other applications vs. exhaust that Baelz thermocompressors can take advantage of.

Thermocompressors can boost low-pressure steam to higher, usable pressures, allowing plants to recycle energy that would otherwise be lost. This not only cuts waste but also helps industries meet growing efficiency and sustainability demands. In this blog, we'll explore thermocompressors and their role in steam recompression.

How Steam Recompression Works

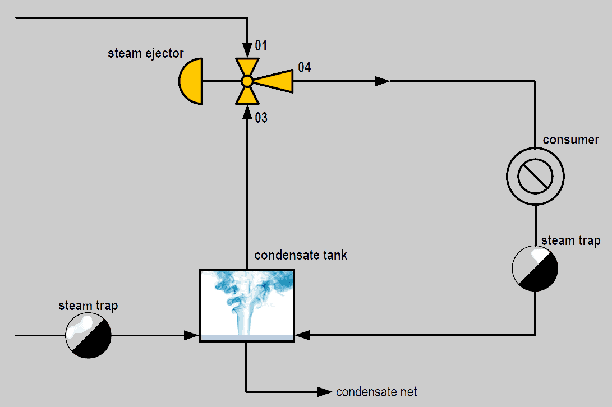

The principle behind steam recompression is straightforward: combining motive steam with low-pressure waste steam and discharging the mixture at a high pressure.

Inside the thermocompressor body, motive steam accelerates through a nozzle, creating a jet that entrains the waste steam in the mixing chamber. The mixed stream then passes through a diffuser, where velocity decreases and pressure increases. The resulting higher-pressure steam is ready for use in industrial operations.

There are two primary approaches to steam recompression:

- Mechanical Vapor Recompression (MVR). Here, a compressor and drive perform the work, similar to equipment used for air or natural gas compression. MVR is often applied in continuous processes requiring steady, mechanical efficiency.

- Thermal Vapor Recompression (TVR). This method utilizes a sonic nozzle jet and high-pressure steam to recompress lower-pressure vapor. This recompressed vapor can then condense and be reused as a heating medium in the same process, making it ideal for plants with an existing steam supply.

Both processes, while different in function, are designed to turn what was once waste into a valuable energy resource.

Uses of Steam Recompression

Thermocompressors are widely applied across industries, from food processing to chemical manufacturing, thanks to their balance of efficiency and versatility.

Food Industry

Thermal recompression can save more than one-third of the steam and water that would otherwise be required. By capturing and recompressing a portion of the steam that is discharged from an evaporator, plants in the dairy processing, and other food sectors can reduce their overall energy demand. Reusing steam in this way improves efficiency while supporting the industry's ongoing push toward sustainable operations.

Chemical Processing Plants

In chemical processing, thermal recompression methods can be used to upgrade low-pressure steam for reuse in chemical reactions. By recovering and reapplying thermal energy, plants can reduce natural gas consumption and lower emissions.

In addition, recompression systems can compress toxic vapors for safe disposal to mitigate environmental and health risks. Plants may be able to recover valuable products from compressed vapors to minimize resource losses and optimize production profitability.

Why Thermocompressors Matter

At their core, thermocompressors help industries do more with less. They can offer a practical path for growth in industries that are wrestling with rising energy costs and tighter environmental standards.

By reusing steam that would otherwise be wasted, using thermocompressors for steam recompression can:

- Improve energy efficiency across plant operations

- Deliver measurable cost savings

- Reduce reliance on fossil fuels

- Lower greenhouse gas emissions

- Enhance safety and compliance

Contact Baelz North America for More

By reducing waste and reclaiming energy, steam recompression makes it possible for companies to optimize resources and improve process control. Baelz North America supplies steam control solutions that drive efficiency and sustainability across various industries, including wood, textile, food, and chemical processing.

Ready to take the next step? Contact us today or request a quote to see how Baelz thermocompressors can improve your plant's energy efficiency and bottom line.